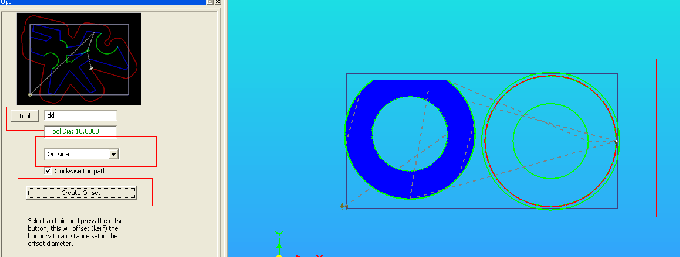

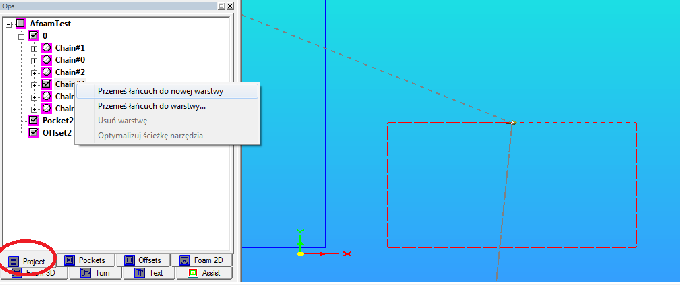

The result of the CAD stage is a drawing, in HPGL or DXF format. Radius compensation is drawing all lines 1.5 mm outside (or inside, for holes) where you actually want the cut, to take account of the milling head removing 3 mm of material. CAD (computer aided design): Drawing is made in Corel Draw, and radius compensation is done.This is normal (although some setups have tighter integration between the programs than we do). The process is divided into 3 steps, which use 3 different programs. TinkerCAD for newbiesįusion 360 for experts (and it includes the CAM step). If you want to get going with a new 3D program, we recommend (as of 9/2014). This guide does not cover 3D milling, for which we use a 3D drawing program such as tinkercad, Fusion 360, (123Design has stopped working), AutoCAD, Rhino, Solidworks, Inventor and plan the job and convert to G-code in MeshCAM or CamBam (or inside Fusion 360). This guide describes how to use Corel Draw (or another 2D vector drawing program such as Inkscape, Illustrator, AutoCAD etc.), Laz圜AM and Mach3 to mill 2D-ish things out of large sheets of material such as plywood, OSB, HDF, MDF, plastic etc. We may fork the guide into two at some point in the future (or more likely, they may get more similar, if we replace the specially skinned Mach3 on the Raptor with the standard Mach3 look). Lines starting with Raptor: or GOSC: indicate something specific to that particular machine.

The workflow is almost the same on the two machines.

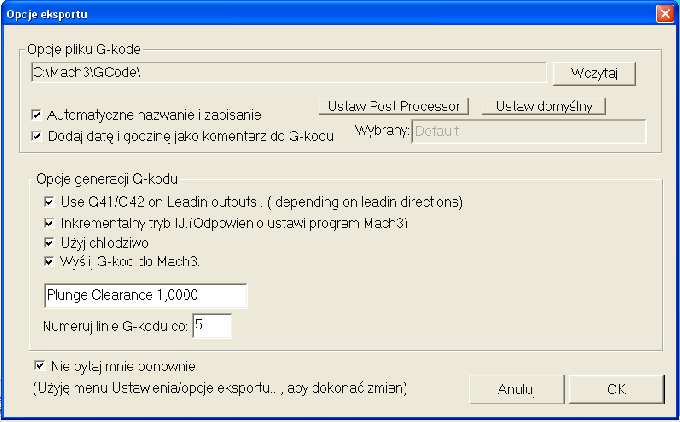

Append a line above with date and version number so we can tell what version printed copies are. Guide to using the large scale CNC machines for 2½ D (flat-ish) milling - the Raptor at FabLab RUC and the Giant Open Source CNC at Illutron. Use the right post-processer for exporting G-Code (Mach3Mill) Guide for 2D geometry make the setup and setting the coordinate system right (see picture above for machine coordinate systemĢ. When making parts in Fusion there is three important things there is important for the machine.ġ. The machine is able to run G-Code written by Fusion. It is possible to cut thicker things, but requires changing to a bigger, thicker tool, so is slower, noisier and you cannot do small details. This is what we do as standard 90% of the time, and the process we recommend as being not terribly painful. Practically, the only process we recommend as being easy is cutting max 12mm wood with a 3mm radius mill. Normally mounted with a Kress 20.000 RPM spindle carrying a 3mm mill, can be equipped with 1-5 mm mills or a plasma cutter. The Z axis has max 110mm travel, which may be reduced by tool length and material thickness. Remember to leave at least 10mm material around the edge and between larger parts. Published: September 29, 2014, Edited by: Mads Hobye CNC milling ĬNC machine for lightweight materials such as plywood, wood, MDF, plastics, nylon, aluminium.

0 kommentar(er)

0 kommentar(er)